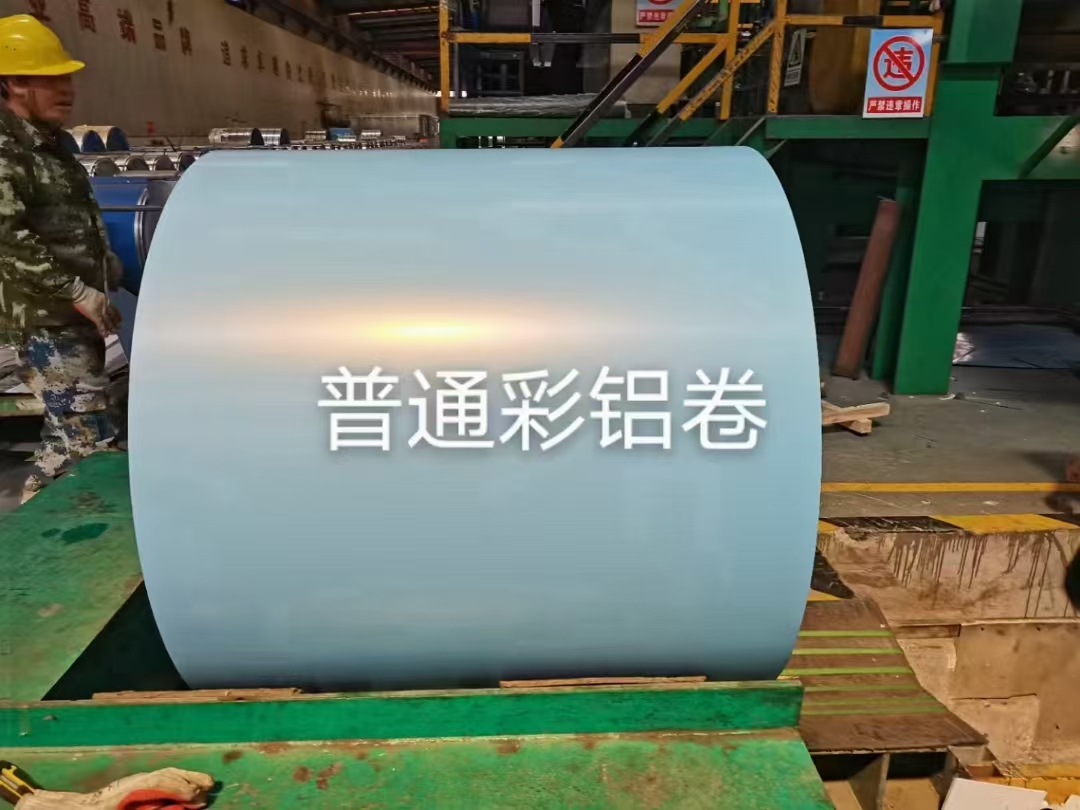

Color coated aluminum coil

所属分类: Color coated aluminum plate

产品简介:Алюминий.pdfColor coated aluminum coil Products used for aluminum-plastic panels, industrial factory roofs and walls, aluminum blinds, composite panels, aluminum ceilings, cans, and electronic productsColor-coated aluminum coil, as the name implies, is to paint and

产品详情

Color coated aluminum coil

Products used for aluminum-plastic panels, industrial factory roofs and walls, aluminum blinds, composite panels, aluminum ceilings, cans, and electronic products

Color-coated aluminum coil, as the name implies, is to paint and color the surface of the aluminum substrate. Common ones are fluorocarbon color-coated aluminum coil and polyester color-coated aluminum coil. They are widely used in aluminum-plastic panels , industrial factory roofs and walls, aluminum blinds, composite panels, aluminum ceilings, cans, and electronic products.

Chinese name

Color coated aluminum coil

Application

Aluminum-plastic panels , industrial factory roofs and walls, aluminum blinds, composite panels, aluminum ceilings, cans, and electronic products.

Introduction

Color-coated aluminum (color-coated aluminum coil), common polyester color-coated aluminum (color-coated aluminum coil), is widely used in aluminum honeycomb panels, aluminum ceilings, roof surfaces, scraps, and its performance is very stable and not easily corroded, a new type of material.

type

Color-coated aluminum coils are divided into: polyester-coated aluminum coils (PE) and fluorocarbon-coated aluminum coils (PVDF). The polyester coating formed by multiple baking on the surface of the aluminum plate can form a firmly attached continuous solid film with protective decorative properties. It is an anti-UV coating. The polyester resin uses a high-molecular polymer containing an ester bond in the main chain as a monomer, and adds alkyd resin . The ultraviolet absorber can be divided into matte and high-gloss series according to the glossiness. It can give color aluminum products rich colors, good gloss and smoothness, as well as superior texture and feel, and can also increase the sense of hierarchy and three-dimensionality. It can protect objects from being exposed to the atmosphere, being attacked by ultraviolet rays, wind, rain, frost, snow and ice; due to temperature differences, freeze-thaw cycles, corrosive gases and microorganisms, the coating can play a protective role. It is especially suitable for interior decoration and advertising boards.

Fluorocarbon coated aluminum coil (PVDF)

Fluorocarbon coating is a coating made of PVDF resin, which mainly refers to vinylidene fluoride homopolymer or copolymer of vinylidene fluoride and other small amounts of fluorine-containing vinyl monomers. The chemical structure of the fluorine acid base material is combined with fluorine/carbon bonds. The stability and firmness of this chemical structure make the physical properties of fluorocarbon coatings different from those of general coatings. In addition to excellent mechanical properties such as wear resistance and impact resistance, it also shows long-term anti-fading and anti-ultraviolet properties, especially in harsh climates and environments. After high-temperature baking and film formation, the molecular structure in the coating is compact and has super weather resistance. Fluorocarbon coatings can be divided into traditional fluorocarbon and nano-fluorocarbon coatings according to the surface film structure. In 1965, Pennwalt Chemical Company in the United States first used fluorocarbon coatings to meet the coating of indoor and outdoor aluminum materials in high-end buildings. The wide range of color options, the solemn appearance of the United States, and durability have added luster to many magnificent curtain wall buildings around the world. The coating manufacturer's guarantee of the service life of the coating started from 10 and 15 years to more than 20 years. American research institutions have conducted tests and comparisons on fluorocarbon coatings, super coatings and general coatings. The samples with different coatings were exposed to the hot sunlight in Florida, USA, and in a harsh environment of humid and salty air for 12 years. It was actually proved that the stability and durability of fluorocarbon coatings are 30 and 80 percentage points higher than the other two coatings. Fluorocarbon coatings can be used in various harsh environments.

It is particularly suitable for decoration and display of indoor and outdoor decoration in public places, commercial chains, exhibition advertisements, etc.

characteristic

Flatness:

There is no composite high temperature indentation on the surface. There is no residual stress on the board surface and it does not deform after shearing.

Decorative:

Paint wood grain and stone grain, with realistic physical texture and fresh natural beauty. The pattern can be made at will, giving customers a wide range of personalized choices, enriching the humanistic connotation of the product and giving people more aesthetic enjoyment.

Weather resistance:

The paint pattern formed by continuous coating and high temperature baking has high gloss retention, good color stability and minimal color difference. The polyester paint has a 10-year warranty and the fluorocarbon paint has a warranty of more than 20 years.

Mechanical:

Made of high-quality aluminum, plastic and adhesive, and using advanced composite technology, the product has the required bending and folding strength for decorative panels, and will not cause bending, deformation, expansion, etc. under the four-season climate conditions and changes in wind pressure, temperature, humidity and other factors.

Environmental protection:

It is resistant to salt, alkali and acid rain corrosion, will not corrode or produce toxic bacteria, will not release any toxic gas, will not cause rust on the keel and fixings, and is flame retardant. According to national regulations, it is not less than B1 grade.

application

Color-coated aluminum coils have a rich range of colors. Whether it is a residential building, a large commercial outlet or a large exhibition center, color-coated aluminum coils can add color to it. Good plasticity and mechanical processing properties make it an ideal material for various architectural shapes. Color-coated aluminum coils have provided architects, designers and owners with a color space for personalized exterior walls and ceilings, and are also the most ideal material for architectural shapes. Whether it is a multifunctional large-scale building or a unique and creative new building, color-coated aluminum coils can always meet the different requirements of modern and classical architectural styles, making the building colorful. The products are used in many fields such as electronic appliances, instruments, lighting, packaging, and home decoration.

The products have a wide range of uses: construction (aluminum-plastic panels, aluminum honeycombs, roof corrugated panels, fireproof veneers, aluminum ceilings, blinds, rolling doors, garage doors, awnings, gutters), electronic appliances (computer cases, electrical panels), lighting, furniture, solar reflectors, air conditioning ducts, etc.