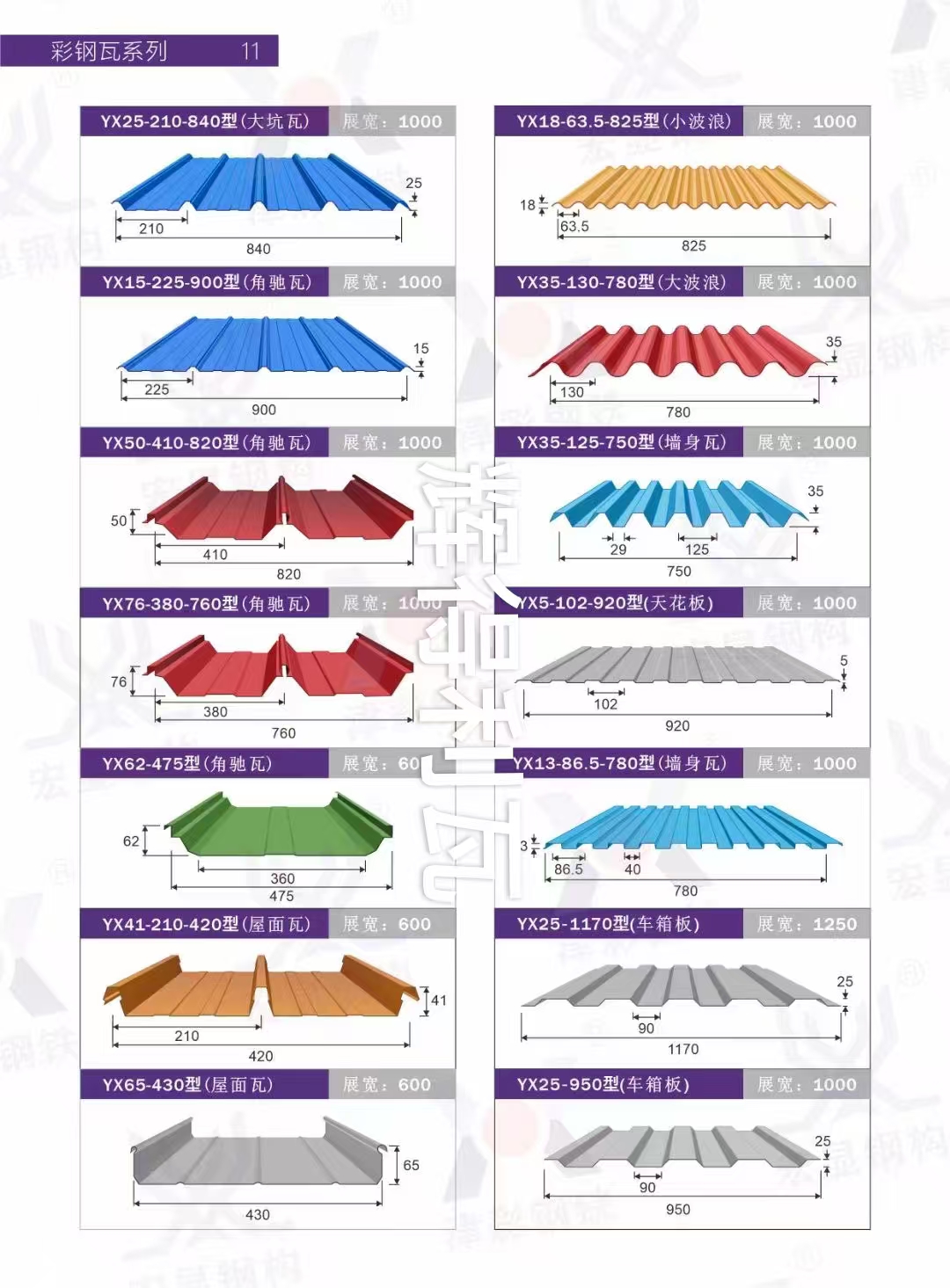

Caigang watts

所属分类: Corrugated board

产品简介:Color steel tiles,also known as colored corrugated tiles, are made ofcolored coated steel plates thatare cold-bentinto various corrugatedprofilesby rollers.It is suitable for roofs, walls, and interior and exterior wall decoration of industrial and civil bui

产品详情

Color steel tiles, also known as colored corrugated tiles, are made of colored coated steel plates that are cold-bent into various corrugated profiles by rollers .

It is suitable for roofs, walls, and interior and exterior wall decoration of industrial and civil buildings, warehouses, special buildings, and large-span steel- structured houses. It has the characteristics of light weight, high strength, rich colors, convenient and quick construction, earthquake resistance, fire resistance, rain resistance, long life, and maintenance-free. It has been widely promoted and used.

Features

⒈Light weight: 10-14 kg/m2, equivalent to 1/30 of a brick wall.

⒉ Thermal conductivity: λ<=0.041w/mk.

⒊ High strength: It can be used as ceiling enclosure structure board to bear weight, resist bending and compression; general houses do not need beams and columns.

⒋ Bright color: No surface decoration is required, the anti-corrosion layer of colored galvanized steel plate can be maintained for 10-15 years.

⒌ Flexible and quick installation: the construction period can be shortened by more than 40%.

Install

Dosage calculation formula

1. Two-sided pitched roof

Two-sided slope roof description

⒈Roof area: length × width.

⒉Total length of tiles required: roof area ÷ 0.855 (effective width of tile is 0.855M/tile).

⒊The number of tiles: (roof length ÷ 0.855m) × 2.

⒋The number of ridge tiles: roof length ÷ 2.4m (the effective length of the ridge tile is 2.4m/root).

⒌The number of sealing strips: (length ÷ 0.7m) × 2 (sealing strip 0.7M/piece).

⒍The number of eave covers: (length ÷ 0.7m) × 2 (eave cover 0.7M/piece).

⒎Number of special nails: 4PCS/㎡.

⒏Roof angle ≤120 degrees.

2. Four-sided slope roof

Four-sided pitched roof description

⒈Estimated roof area: (A+B+C+D)×117% (tilt and loss).

⒉Total length of tiles required: roof area ÷ 0.855 (effective width of tiles is 0.855M/tile).

⒊Number of ridge tiles: (a×2+b+c×2)÷0.7 (the effective length of the ridge tile is 2.4M/root).

⒋The number of sealing strips: (length + width) ÷ 0.7 (sealing strip 0.7M/piece).

⒌The number of eave covers: (length + width) × 2 ÷ 0.7 (eave cover 0.7M/piece).

⒍Number of special nails: 4PCS/㎡.

Pre-installation engineering

Four-sided slope

1: The blue dotted line and the red dotted line are the horizontal and vertical skeletons respectively.

2: a The best distance is 50CM.

3: The best distance between b is 50-70CM.

Two-sided slope

⒈ Choose the material of the frame, both wooden and steel structures are suitable.

⒉The construction surface needs to be smooth.

⒊ Specifications of skeleton materials : Wood specifications are above 45MM×45MM, and steel specifications are above 40MM×40MM.

4. The longitudinal spacing of the frame should be kept between 50CM and 70CM, and the transverse spacing must be a multiple of 25CM, preferably no larger than 50M. Use screws as tightly as possible and weld firmly. [1]

Installation Engineering

1. The correct way to lay tiles

⒈Overlap type (applicable to roofs with a length of ≤15M)

⒉Staggered type (applicable to roofs with a length of ≧15M)

2. Correct use of special nails

⒈ Special nails must be hammered in the middle of the tile frame to achieve a waterproof effect.

⒉The horizontal and vertical intervals of special nails are 50CM~100CM (preferably 4 nails/㎡).

⒊ Special nails must be driven from the bottom of the tile toward the roof to achieve a beautiful, sealed and neat effect.

3. Install the sealing strip ridge tile eaves cover

⒈ Separate the sealing strip into two halves, press it on the roof according to the tile pattern, cover the ridge tiles and fix them with special nails.

⒉ At the junction of the side tiles, seal it with cement and then directly cover it with the ridge tile. Finish the bottom of the ridge tile with a small tile stopper.

⒊ Install the eaves cover directly at the lower end of the tile, i.e. the eaves, and fix it with screws.

4. At the junction of the ridge tiles, trim the interface with scissors, overlap it and seal it with glass glue.

4. Waterproof treatment of protruding parts

First, make a V-shaped material. Different materials and specifications can be selected, depending on the actual situation. Make the water inlet and install it at the bottom, then lay the color steel tiles on it.

5. Inclined surface connection installation

Refers to the construction of installing water collection treatment at the bottom after two roof tiles are cut according to angle and length. First, install water collection materials (i.e. gutters) under the tiles, and then use waterproof adhesive or cement for finishing.

Precautions

1. Wear necessary safety equipment (such as gloves, helmets, safety belts and other tools).

2. Installers must be certified professionals.

3. The frame must be installed firmly.

4. When walking on the tiles during installation, try to step on the middle part of the tiles and avoid stepping on the edges of the tiles.

5. Be careful when installing in bad weather. [1]