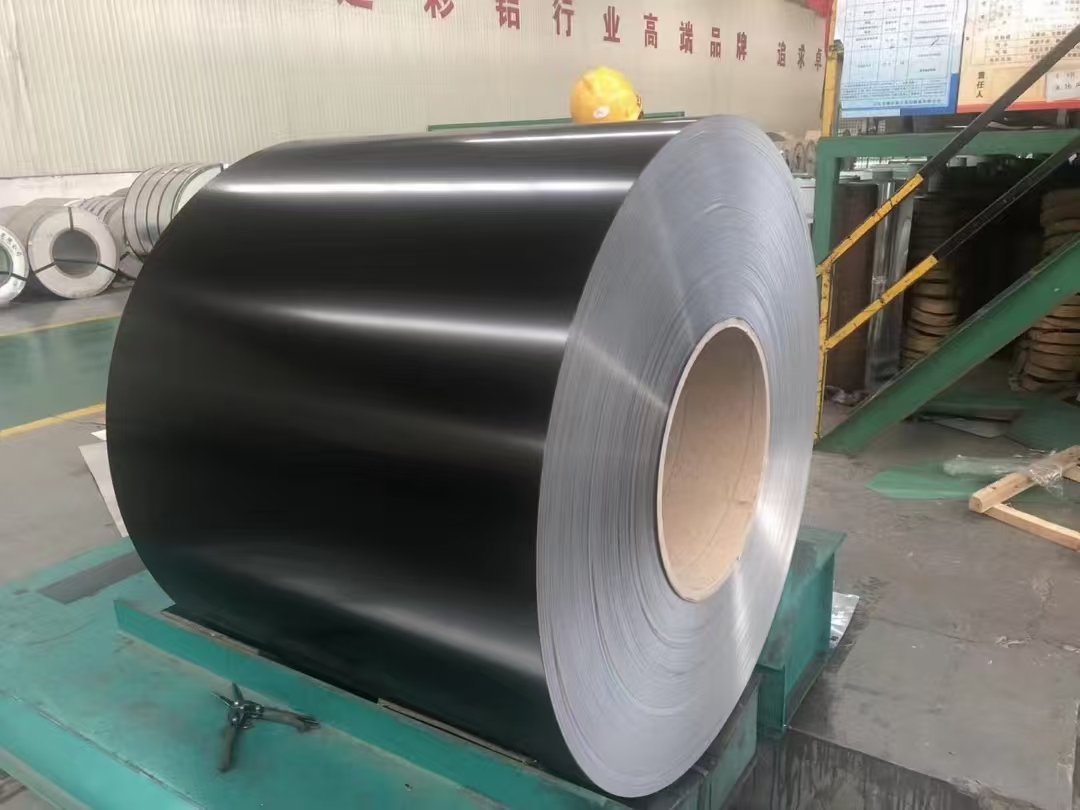

Home appliance panel

所属分类: Color coated sheet roll

产品简介:Color-coated panels for homeappliancesare1。RationaleThe basic principle of home appliance color-coated plates includes the following steps:Surfacetreatment: Before color-coated panels are processed, the surface of home appliances needs to be degreased, rust-removed, polished

产品详情

Color-coated panels for home appliances are1。

Rationale

The basic principle of home appliance color-coated plates includes the following steps:

Surface treatment : Before color-coated panels are processed, the surface of home appliances needs to be degreased, rust-removed, polished, etc. to ensure the adhesion between the coating and the substrate.

Spraying process : Use a pneumatic spray gun to spray the paint. By controlling the spray pressure, nozzle shape and paint flow of the spray gun, uniform coverage of the product surface can be achieved.

Curing treatment : After spraying, curing treatment is usually carried out by baking or ultraviolet irradiation, so that the coating can harden quickly and improve its wear resistance and scratch resistance1。

Application Areas

Household appliance color-coated plates are widely used in various household appliances, including but not limited to refrigerators, washing machines, air conditioners, microwave ovens, range hoods, gas stoves, etc. For example:

Refrigerator : Due to the large size of refrigerators and the diverse surface requirements, the application of color-coated plate technology is very common, which can present a variety of colors, patterns and textures to meet the personalized needs of different consumers.

Washing machine : Through color-coated plate technology, the surface of the washing machine can have properties such as waterproof and anti-pollution, while achieving diversified appearance.

Air conditioner : Color-coated plate technology is often used on the external and internal parts of air conditioner products to improve the appearance and performance of the products.1。

Material composition and performance characteristics

Home appliance color-coated plates are usually based on electro-galvanized and cold-rolled plates. The surface coating is composed of chemical components such as polyester (PE), fluorocarbon (PVDF), polyester resin, etc., and has excellent properties such as weather resistance, corrosion resistance, anti-fouling, and UV resistance. Common substrates include:

Galvanized steel sheet : It is corrosion-resistant and durable, and is widely used in building facade decoration.

Aluminum plate : Lightweight and corrosion-resistant, suitable for the construction and home appliance industries.

Stainless steel plate : With excellent corrosion resistance and high strength, it is suitable for high-end decorative applications。