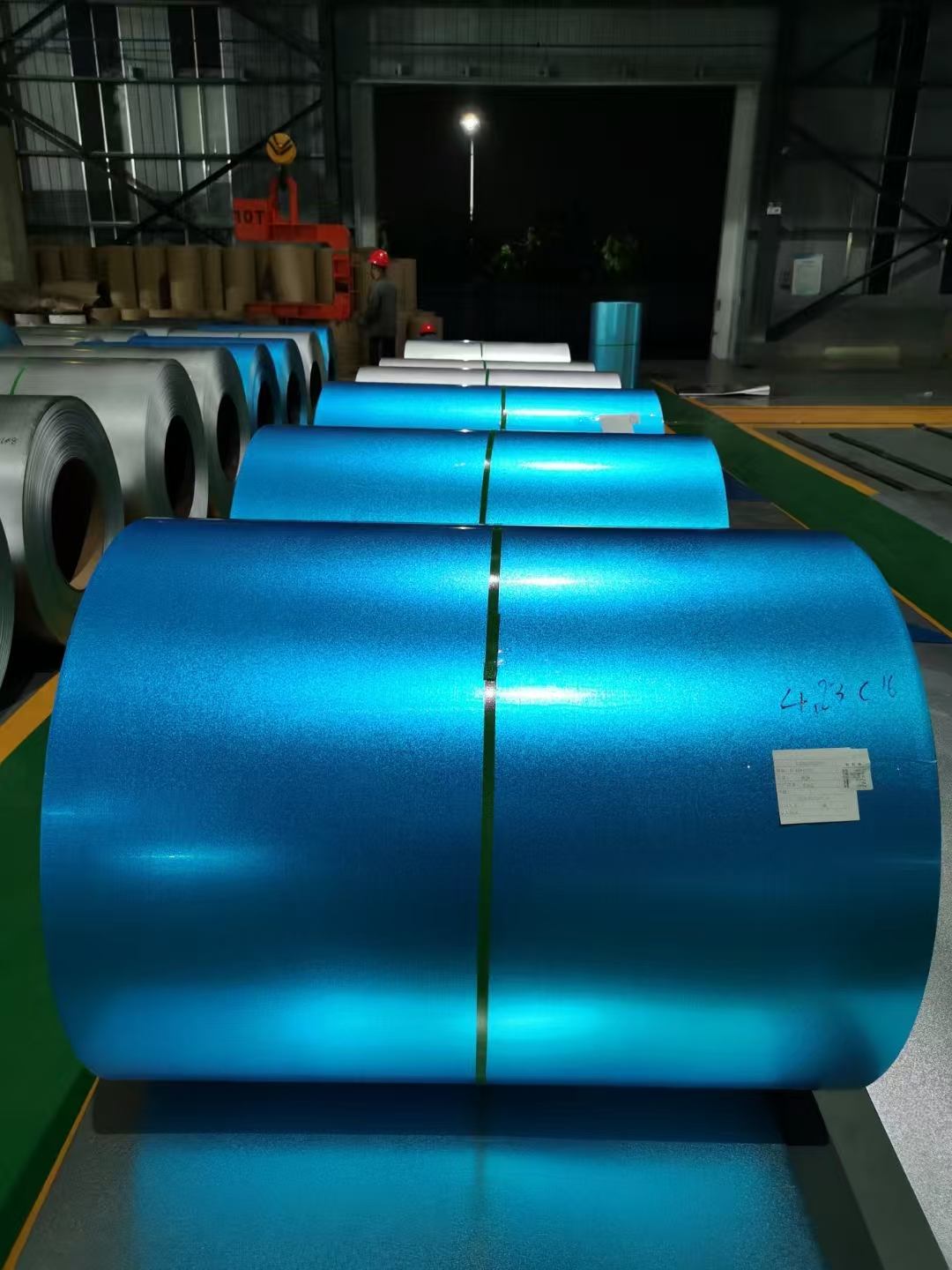

Anti-fingerprint galvanized sheet (roll)

所属分类: Galvanized series

产品简介:Fingerprint-resistant boardComposite coating boardAnti-fingerprint sheet is a composite coating sheet obtained by anti-fingerprint treatment on the surface of galvanized sheet. The surface of anti-fingerprint steel sheet is smooth and flat with small tolerance. The earliest anti-fingerprint treatmen

产品详情

Fingerprint-resistant board

Composite coating board

Anti-fingerprint sheet is a composite coating sheet obtained by anti-fingerprint treatment on the surface of galvanized sheet. The surface of anti-fingerprint steel sheet is smooth and flat with small tolerance. The earliest anti-fingerprint treatment technology used was a coating containing hexavalent chromium. Domestic and foreign countries generally use the process of passivating galvanized sheet and then applying an organic coating (anti-fingerprint film) on the passivation film to produce anti-fingerprint sheet.

In addition to some special processes, the early use of anti-fingerprint treatment technology is a coating containing hexavalent chromium. As environmental regulations become more and more stringent, hexavalent chromium technology is gradually replaced by trivalent chromium technology and chromium-free technology. Modern chromium-free technology not only has the corrosion resistance of chromium-containing technology, but also has the multifunctionality that chromium-containing technology does not have. It is widely used in home appliances, electronics and construction markets.

Anti-fingerprint sheet is a composite coating sheet obtained by anti-fingerprint treatment on the surface of galvanized sheet . Anti-fingerprint steel sheet is the earliest material to pass environmental certification. It is named "anti-fingerprint" because it does not leave fingerprints when touched with clean fingers. The surface of anti-fingerprint steel sheet is smooth, flat and has a small tolerance. The research and production of anti-fingerprint sheet originated in Japan and entered commercial production in the early 1980s. Anti-fingerprint treatment was originally intended to meet the requirements of users in the field of home appliances. In the production process of home appliances, many parts are touched many times by workers due to process requirements. The sweat on the hands of workers forms pollution on the surface of the parts, affecting the appearance. Therefore, anti-fingerprint sheet was developed. [1]

Cause

Anti-fingerprint treatment was originally developed to meet the needs of users in the field of home appliances . In the production process of home appliances, many parts are touched by workers many times due to process requirements. The sweat on the hands of workers will pollute the surface of the parts, affecting the appearance. Therefore, anti-fingerprint plates were developed.

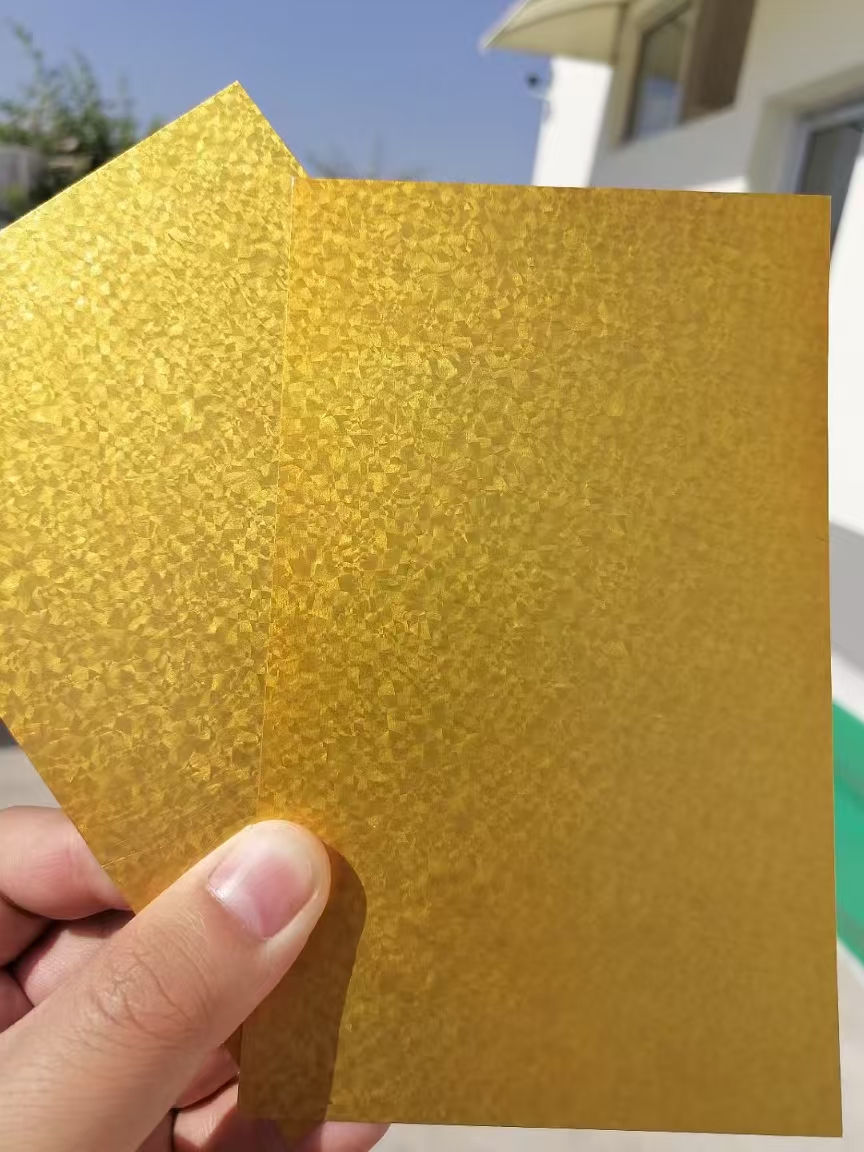

type

One type is that the galvanized sheet is passivated and then an organic coating (anti- fingerprint film ) is applied on the passivation film, and the coating method is mainly roller coating.

The other is to add organic resin and colloidal silica to the passivation solution of galvanizing . After the galvanized strip passes through the passivation tank, a composite coating with corrosion resistance and fingerprint resistance is formed on its surface. The coating methods are mainly electrolytic coating and roller coating. The first process is generally used to produce fingerprint-resistant panels at home and abroad. Traditional fingerprint-resistant panels are basically based on electrogalvanized panels as substrates. With the continuous improvement and development of hot-dip galvanizing technology and processes, the surface quality of hot-dip galvanized panels has reached a level comparable to that of electrogalvanized panels, while hot-dip galvanized panels are cheap and have better corrosion resistance. Therefore, hot-dip galvanized panels are gradually becoming the mainstream as fingerprint-resistant substrates. In addition, in 2007, organic composite coating panels that have multiple properties (such as fingerprint resistance, conductivity , self-lubrication, paintability, etc.) and can meet multiple usage requirements at the same time are developing rapidly.

The main use of thin organic coated steel sheets with fingerprint resistance is the inner and outer panels of various household appliances. The largest demand for fingerprint-resistant sheets in China is in the computer case manufacturing industry, with an estimated annual consumption of 400,000 to 500,000 tons. [2]

use

Electro-galvanized anti-fingerprint sheet is a high value-added product among cold-rolled products, and is widely used in office equipment, micro-motors, home appliances , computers and other industries. Internationally renowned companies have set up factories in China to assemble and produce printers and LCD screens . For core steel parts such as printer linings, brackets and LCD panels, users have put forward extremely high requirements for electro-galvanized anti-fingerprint sheet. Due to the limited domestic technical level, these companies have been using imported products.