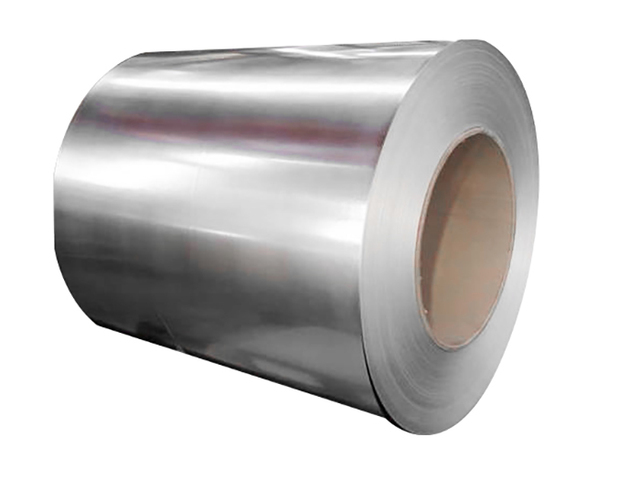

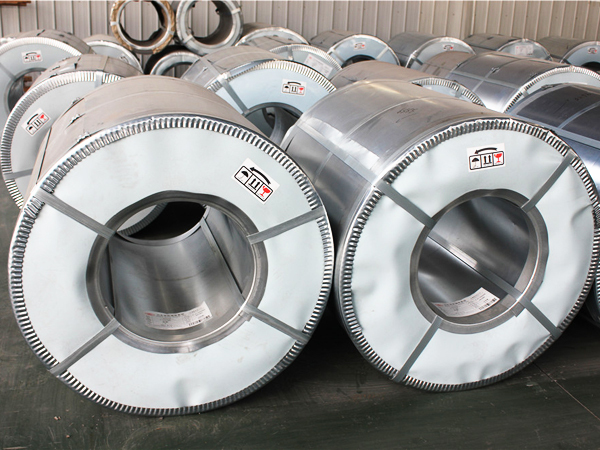

Galvanized sheet (roll)

所属分类: Galvanized series

产品简介:Hot dip galvanized sheetHot-dip galvanized sheet is a material formed by combining steel and zinc. It is galvanized by immersing the treated steel strip directly into molten zinc liquid. This method makes the hot-dip galvanized sheet have the strength and plasticity of steel, and at the same t

产品详情

Hot dip galvanized sheet

Hot-dip galvanized sheet is a material formed by combining steel and zinc. It is galvanized by immersing the treated steel strip directly into molten zinc liquid. This method makes the hot-dip galvanized sheet have the strength and plasticity of steel, and at the same time has a corrosion-resistant coating. It is widely used in construction, home appliances, automobiles and other fields.

Common types of hot-dip galvanized steel sheets include: general commercial coils (CQ), structural galvanized sheets (HSLA), stamping galvanized sheets (DQ), deep drawing hot-dip galvanized sheets (DDQ), bake hardening hot-dip galvanized sheets (BH), duplex steel (DP), TRIP steel ( transformation induced plasticity steel ), etc.

1. Hot-dip galvanized steel sheet: immerse the thin steel sheet in a molten zinc tank to make a layer of zinc thin steel sheet adhere to its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel sheet is continuously immersed in a molten zinc plating tank to make a galvanized steel sheet ; alloyed galvanized steel sheet. This steel sheet is also made by hot dip method , but after leaving the tank, it is immediately heated to about 500℃ to form an alloy film of zinc and iron . This galvanized sheet has good coating adhesion and weldability .

2. Hot-dip galvanizing can be divided into two types according to the annealing method: in-line annealing and off-line annealing, which are also called protective gas method and flux method respectively.

defect

The main ones are: falling off, scratches, passivation spots, zinc particles , thick edges, air knife streaks, air knife scratches, exposed steel, inclusions, mechanical damage, poor steel base performance, wavy edges, warping , inconsistent dimensions, embossing, inconsistent zinc layer thickness, roller marks , etc.

The main reasons for the zinc layer falling off are: surface oxidation, silicon compounds, the cold rolling emulsion is too dirty, the oxidizing atmosphere and protective gas dew point of the NOF section are too high, the air-fuel ratio is unreasonable, the hydrogen flow rate is low, oxygen infiltration into the furnace, the strip entering the pot temperature is low, the RWP section furnace pressure is low and the furnace door suction, the NOF section furnace temperature is low, the grease is not completely evaporated, the aluminum content of the zinc pot is low, the unit speed is too fast, the reduction is insufficient, the residence time in the zinc liquid is too short, and the coating is too thick.

The causes of white rust and black spots are: black spots are formed by further oxidation of white rust.

The main causes of white rust are:

(1) Poor passivation , insufficient or uneven passivation film thickness;

(2) The surface is not oiled or there is residual moisture on the surface of the strip;

(3) The strip surface contains moisture when coiling;

(4) The passivation was not completely dried;

(5) Affected by moisture or rain during transportation or storage;

(6) Finished products are stored for too long;

(7) Galvanized sheets are in contact with or stored together with other corrosive media such as acids and alkalis.

Finished products are allowed to be stored in the warehouse for up to three months to avoid oxidation due to prolonged storage.

length

Negative tolerance is not allowed for the length of galvanized steel sheets , and the maximum tolerance is not allowed to exceed +6mm.

The difference between hot-dip galvanized sheet and electro-galvanized sheet

Hot-dip galvanized sheet is hot-rolled galvanized sheet , and cold-dip galvanized sheet is cold-rolled galvanized sheet. In terms of materials, the composition of the two galvanized sheets is basically similar. The difference is that cold-dip galvanized sheet is thinner than hot-dip galvanized sheet, has better surface quality, and more complicated process. The price is also higher.

From a technical point of view, steel is sent from ingot to hot rolling and rolled into a plate of a certain thickness , such as about 10mm. If the user has no higher requirements for the surface, thickness, and mechanical strength of the plate, it can be processed into a finished product, such as galvanizing, and sold directly, that is, hot plate. If there are higher requirements for the plate, the hot-rolled plate will be sent to the cold rolling line for further processing. After pickling, annealing, and re-rolling, a thinner, smoother surface, and better mechanical properties of cold-rolled plate can be obtained.

Hot dip galvanizing process production process

Raw materials (cold-rolled steel coil) → uncoiling → cutting head and tail → welding → alkali solution spraying → alkali solution brushing → electrolytic degreasing → water brushing → hot air drying → entrance looper → reduction annealing → hot dip galvanizing → zinc layer control (air knife) → cooling → skin finishing → stretching bending straightening → purification → drying → export live → unloading coils → steel coil weighing → packaging → storage

Application fields of galvanized sheet

镀锌板行业应用已经很普遍,镀锌薄板主要应用于汽车工业、冷藏车、建筑行业、自然通风和供暖设备及其家俱生产制造等行业,主要包含以下工程建筑、家用电器、家俱、运送、钢制品和别的日常生活用品等行业。

Galvanized sheets are used in the construction industry: roofs, prefabricated roof components, living balcony control panels, balconies, newsstands, warehouses, electric rolling doors, electric heaters, precipitation pipes, etc.

Galvanized sheets are used in electrical products: refrigerators, fully automatic washing machines, high-voltage switch cabinets, air conditioners, microwave ovens, bread machines, printers, vending machines, fans, vacuum cleaners, etc.

Galvanized sheets are used in the home decoration industry: lamp covers, wardrobes, dining tables, bookcases, bank counters, billboards, medical equipment, etc.

Galvanized sheets are used in the transportation industry: car ceilings, car bodies, car body panels, large tractors, electric vehicles, shipping containers, highway walls, cargo ship bulkheads, etc.

Galvanized sheets are used in other areas: traditional musical instrument cases, trash cans, advertising signs, clocks, photographic equipment, meters, etc.

Galvanized sheets are used in other steel product manufacturing industries: Color coated steel sheets are based on hot-dip galvanized sheets, hot-dip aluminum-zinc sheets, electro-galvanized sheets, etc., and are made through deep processing technology of color coating production lines. They are widely used in the construction field.